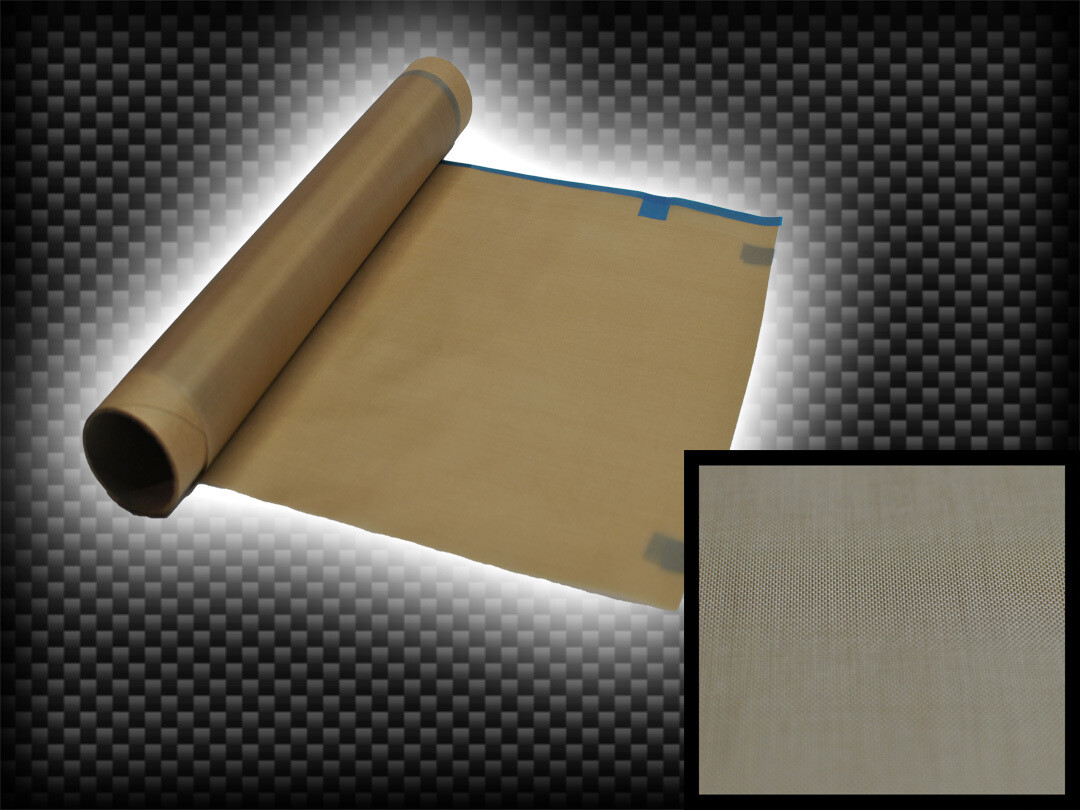

Teflon Coated Fiberglass - Porous

Unit of measure (MOQ): 1 Yard – .003” thick x 19” wide x 1 yard long

Description: BMTCFP is used the same as perforated parting film. Use this material directly over the layup to allow out gassing of air during the curing process. When used correctly the Teflon coated fiberglass will make the laminate smoother and achieve higher resin content. Having the capability to work up to 400 degrees this is the ideal low cost versatile release film. Teflon coated fiberglass is designed to release from all commercial resin systems without the transfer of the resin.

Application: To start the application process, cut the material to the desired size and dimensions paying close attention to cut the material about 2” larger that the largest ply of composite material. Tape in place using blue flash tape. Make sure the BMTCFP is laying flat with no wrinkles, once satisfied with the position on the material proceed with the layup, and or bagging process. Remember that this material does not stretch. After the material has cured, simply remove the BMTCFP for a clean contaminated free surface. This material may be saved and reused.